Minimum 3 Meters clearance provided below Units Pipe racks not crossing any roads. WALTER ABSTRACT Pipe racks are structures in petrochemical chemical and power plants that are designed to support pipes power cables and instrument cable trays.

Pipe Rack Design And Calculations Make Piping Easy

Generally speaking what we didnt do was take wind blowing in a parallel direction with pipe axes inside the rack so the wind and thermal load seldom added together in a long pipe rack design.

. We used 10 of total pipe load as a lateral. -Piping Pipe Support and Structural Design -3D Modeling Technology -Pipe Stress Analysis in which we use Caesar II -For Structural Analysis we use STAAD II -Our engineering and design department uses Finite Element Analysis for many projects. In this case the E-W pipe rack height will be 12 from grade and the N-S pipe rack height will be 15 from grade.

Design of Structural Steel Pipe Racks RICHARD M. Because it is located in the middle of the most plants the pipe rack must be erected first before it becomes obstructed by rows of equipment. A transposition drawing takes the.

Pipe thermal load is parallel with pipe axis. Pipe racks carry process utility pipings and may include instruments cable trays also. Pipe is an industrial plant must be maintained.

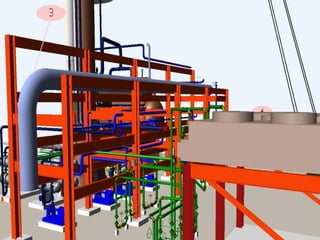

Modular Designed Pipe Rack. Intro Pipe racks are tailor-made to a particular plant. Most design practitioners use the ASCE 7 wind load requirements.

Large size or heavy weight pipes should be located at the lower level and on extreme sides. And resolution of design related issues Purchasers Management representation to be assigned to. As with all engineering design understand the purpose and operation of the system before performing the detailed design.

If the support beam was concrete the thermal load was dead load factored wind was live. They may also be used to support mechanical equipment vessels and valve access platforms. Pipe racks are non-building structures that have similarities to structural steel buildings.

Width of Pipe rack. A pipe rack is the main artery of a process unit. Some of these points are covered in following pipe rack design checklist.

DRAKE and ROBERT J. Wind drift with the full wind load should not exceed the pipe rack height divided by 100. The width of the rack shall be 6 m 8 m or 10 m for single bay and 12 m 16 m or 20 m for double bay having 4 tiers maximum.

They may also be used to support mechanical equipment vessels and valve access platforms. Occasionally pipe racks may also support mechanical equipment vessels and valve access platforms. In multilevel pipe racks pipe carrying corrosive fluids should be on the lower level and utility lines should be at the upper floor.

Pipe must always be viewed as a system from equipment to equipment including branch lines and pipe supports. It is also an important cost factor. 25 Extra space provided for future expansion.

Consider partial wind load Wp. Ad Download 100s of Presentations Graphic Assets Fonts Icons More. Modular Designed Boiler Feed Water Pumps and Piping.

It connects all equipment with lines that cannot run through adjacent areas. Our engineering and design department is involved in the following processes. This is usually done during the plot plan development by creating a piping transposition drawing from PIDs and a preliminary equipment layout.

Process lines are usually on a lower level while. Pipe racks are necessary for arranging the process and utility pipelines throughout the plant. All piperack longitudinal beam struts shall be designed for a compression load of 15 of the maximum adjacent column load at beam level.

The PIP Structural Design Criteria prescribes that wind loads for pipe racks are determined in accordance with ASCE 7 and the following. Pipe racks are structures in petrochemical chemical and power plants that are designed to support pipes power cables and instrument cable trays. Wini Sapong Created Date.

Lot of care planning coordination with other groups needed as mistakes can be very costly. Main pipe racks generally transfer process material between equipment and. A Pipe rack is a structure designed and installed specifically to support multiple pipes where an adequate building or structure is not available mainly outside the building.

It is commonly thought that properly. This checklist can be used at design stage as well as during 3D Model Review. Pipe racks carry process utility piping and also include instrument and electrical cable trays as well as.

Where the pipe rack support air coolers the preferred width should be the width of air coolers. The spacing between pipe rack portals shall be taken as 6m in general. -FEA is used for Special Stress.

There are several ways to determine the width of a pipe rack. Industrial Plant Pipe Rack Foundations Analysis and Design Industrial pipe racks typically support pipes power cables and instrument cable trays in petrochemical chemical paper mills and power plants. For offplot pipe racks longitudinal beam struts shall be designed for vertical and horizontal loads imposed by expansion loops located by piping group.

Piperack structure is a major item and is often fire proofed. However it can be increased to 8m depending on the size of the pumps to be housed below the pipe rack.

Pipe Rack And Rack Piping A Presentation With Pdf What Is Piping

0 comments

Post a Comment